X-ray fluorescence (XRF) Testing

In the electronic component industry, product quality and compliance with environmental standards are among the top concerns for both manufacturers and consumers. To ensure that electronic components on the market meet the highest safety standards, our electronic component laboratory utilizes advanced X-ray Fluorescence Spectrometry (XRF) testing technology. This method allows us to accurately and quickly assess the content of hazardous substances in components, ensuring all products comply with strict environmental regulations, such as the European Union's RoHS directive.

Introduction to XRF Technology

X-ray Fluorescence Spectrometry is a non-destructive testing technology that analyzes the types and amounts of elements in materials by measuring the response to incident X-rays. When X-rays are directed onto a sample, atoms absorb energy and excite electrons. As excited electrons return to their ground state, they emit characteristic X-rays. By analyzing the energy and intensity of these X-rays, the types and amounts of elements in the sample can be determined.

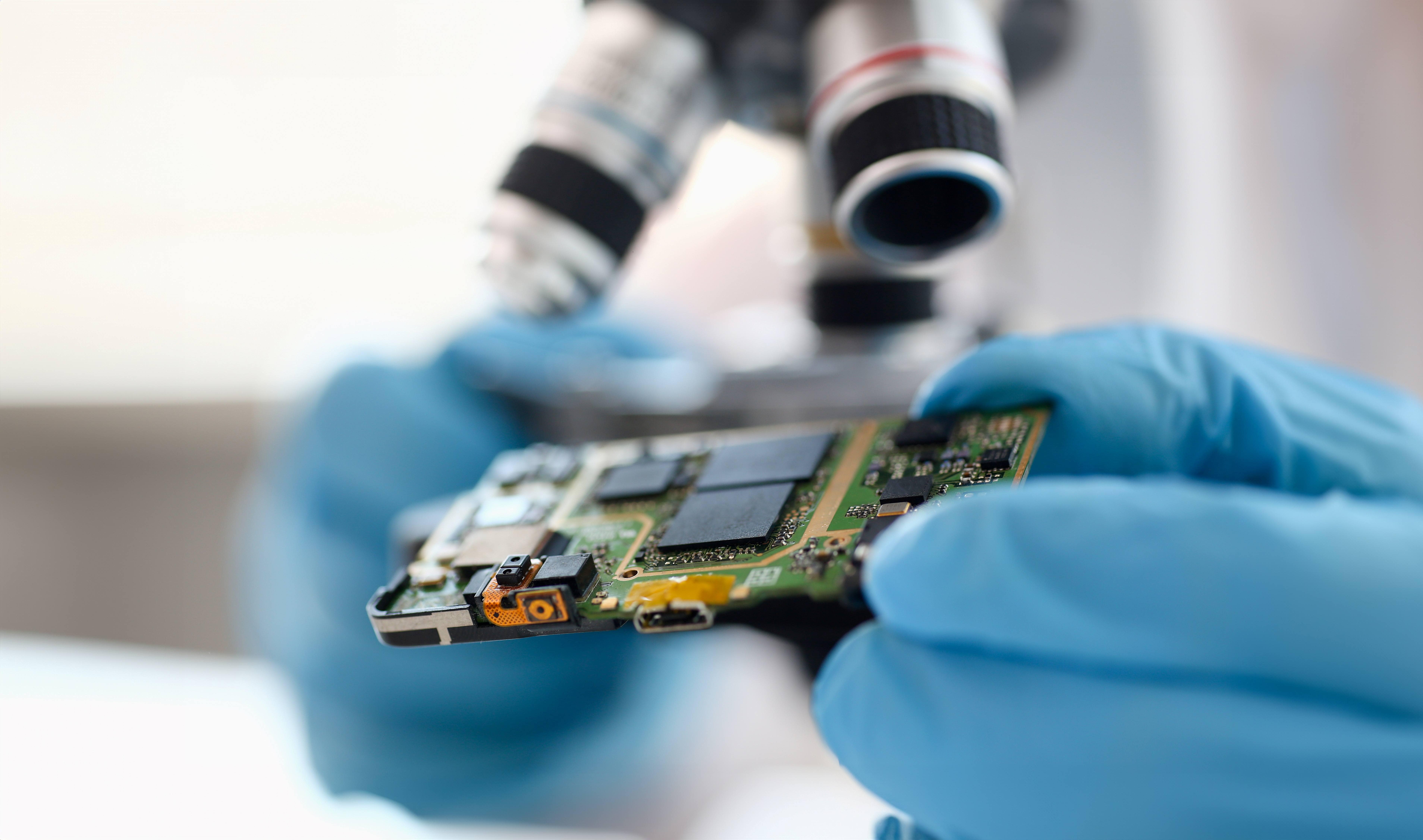

XRF Testing Process

Following the International Electrotechnical Commission standard IEC 62321-3-1, our testing process is rigorously standardized to ensure accuracy and repeatability of each test. This standard provides detailed guidance on using XRF technology to detect heavy metals and other hazardous substances in electronic products, including lead, mercury, cadmium, hexavalent chromium, polybrominated biphenyls, and polybrominated diphenyl ethers. Our laboratory personnel are professionally trained, proficient in this technology, and regularly calibrate and maintain equipment to maintain high testing standards. The specific process includes:

● Sample Preparation: Initially, samples are randomly selected from each batch of products to ensure they represent the quality of the entire batch. The sample surface must be cleaned to avoid dust or oil affecting the test results.

● Equipment Calibration: Before starting testing, we calibrate the XRF equipment using standard samples to ensure the accuracy and consistency of the test data. This step must be performed regularly to address potential equipment deviations.

● Testing Execution: Samples are placed in the sample chamber of the XRF analyzer, and the device automatically adjusts the appropriate testing position and parameters. An X-ray beam irradiates the sample, exciting it to emit characteristic X-rays, which are collected by a detector and converted into elemental analysis data.

● Data Analysis: Software analyzes the data collected by the detector, identifying the types and amounts of elements in the sample. We particularly focus on hazardous substances specified by RoHS, such as lead, mercury, cadmium, and hexavalent chromium.

● Results Evaluation and Reporting: After analysis, technicians evaluate the data to ensure all components meet the specified safety standards. Products that pass are approved to proceed to the next sales or production process, while those that fail require further handling.

Key XRF Testing Equipment

The XRF analyzers we use are among the most advanced on the market, featuring high sensitivity and rapid response capabilities. This equipment provides precise elemental analysis, effectively identifying and quantifying hazardous substances in samples. The maintenance and operation of the equipment are handled by a professional technical team, ensuring each test achieves high standards of accuracy and reliability.

By employing X-ray Fluorescence Spectrometry, our laboratory not only helps clients comply with regulations but also identifies issues before products enter the market, avoiding potential legal risks and damage to brand reputation. The application of this technology strengthens our control over the quality of electronic components, thus providing additional confidence and assurance to our customers, ensuring they receive products that are safe and environmentally friendly.