Solvent Resistance Testing

Resistance to Solvent Testing (RTS) is a crucial quality control method used to assess the durability of electronic components and printed circuit boards when exposed to various solvent environments. This testing helps ensure that the surface markings, coatings, and printed circuits of components do not suffer damage or degradation during practical use. RTS testing is widely applied in multiple industries, including electronics manufacturing, aerospace, and medical equipment, to ensure product durability and reliability.

Basic Principles and Importance of RTS Testing

RTS testing involves exposing components to specific solvent environments and then assessing changes in their surface markings, coatings, and electrical performance. Common solvents include alcohol, acetone, and other chemical reagents. This method detects the adhesion of component surface markings and the solvent resistance of coatings and printed circuits.

For electronic components and printed circuit boards, solvent resistance is key to maintaining stable performance under various environmental conditions. Particularly in fields like aerospace and medical equipment, which demand high reliability, RTS testing provides crucial quality assurance to prevent failures due to peeling surface markings or degrading coatings.

RTS Testing Process

Test Preparation:

● Define testing objectives and requirements, selecting appropriate solvents and testing parameters.

● Prepare test samples, ensuring clear identification for traceability and record-keeping.

Solvent Exposure:

● Immerse or wipe components or circuit boards with designated solvents, setting exposure time and temperature.

● Record environmental parameters during exposure to ensure test repeatability and accuracy.

Performance Evaluation:

● Check the integrity of component surface markings and the solvent resistance of coatings.

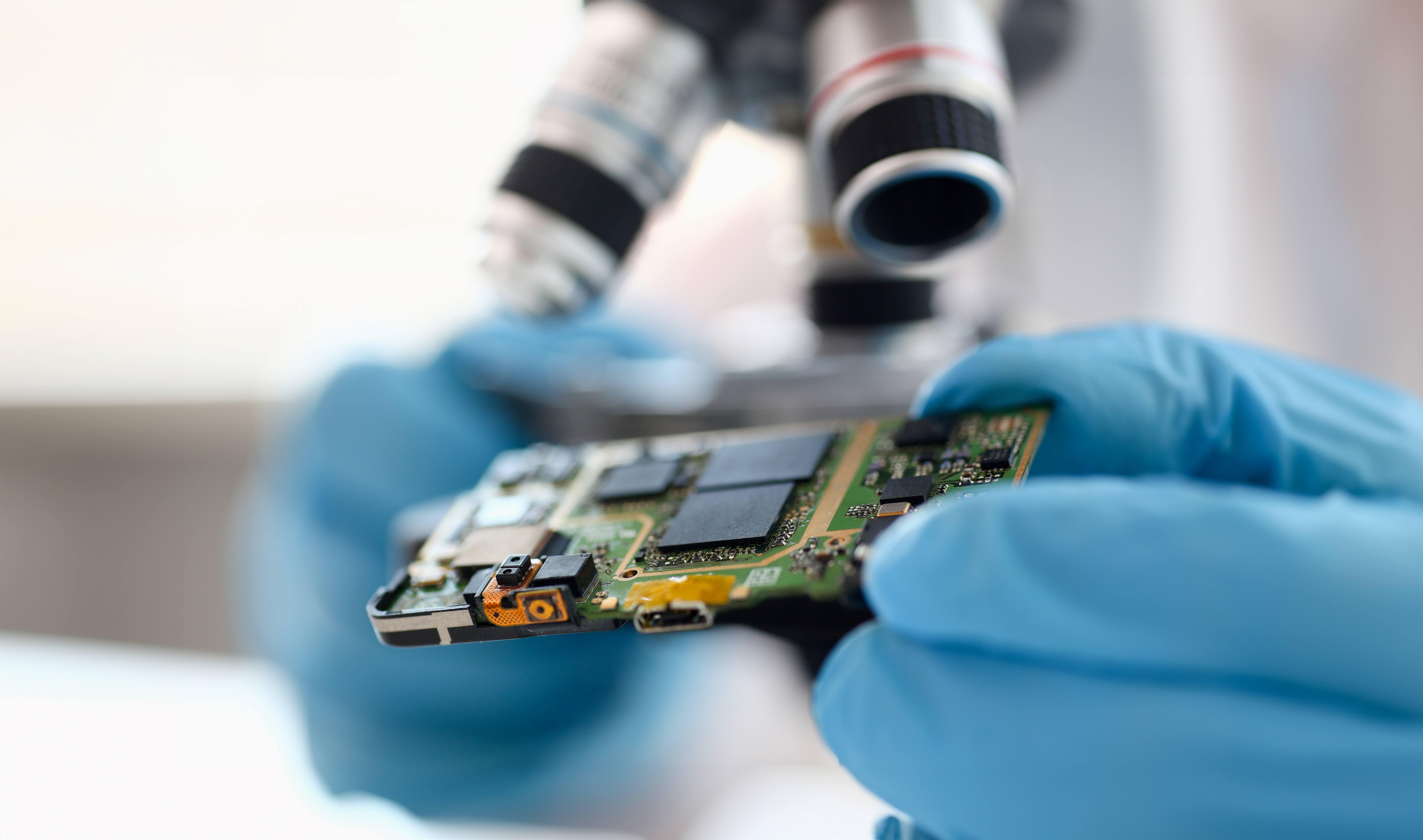

● Use microscopes or other analytical tools to assess the integrity of printed circuits and any potential damage.

Report Compilation and Result Interpretation:

● Document test results in detail, including any identified issues and potential quality risks.

● Prepare comprehensive inspection reports for subsequent quality control and improvement reference.

RTS Testing Equipment

● Solvent testing tanks: Used to house solvents and test samples, ensuring uniform exposure of samples in solvents.

● Microscopes and imaging equipment: Employed to detect and document changes in surface markings, coatings, and printed circuits. High-resolution microscopes can reveal minute damages and defects.

In our laboratory, Resistance to Solvent Testing is an essential means of ensuring the quality and reliability of electronic components and printed circuit boards. By utilizing advanced testing equipment and techniques, we provide our clients with precise, detailed analyses of solvent resistance performance. This not only helps clients identify and avoid potentially defective components but also enhances the overall reliability and market competitiveness of their products. Our testing services ensure that clients can confidently select and use the highest quality electronic components, thereby achieving superior product performance and safety.