Acetone Testing

Acetone testing is a common quality control method to assess the tolerance of electronic components, printed circuit boards, and other electronic materials to acetone exposure. This test helps determine the stability and durability of products when exposed to solvents, ensuring they remain free from failures or performance degradation in real-world applications. Acetone testing finds widespread application across industries such as electronics manufacturing, aerospace, automotive, and medical devices, providing crucial product quality assurance.

Basic Principles and Importance of Acetone Testing

Acetone testing involves exposing test samples to acetone solutions and evaluating changes in their physical and electrical properties to assess their acetone resistance. This test primarily targets surface markings, coatings, and printed circuits of components to check their stability in acetone solutions.

For electronic components and printed circuit boards, acetone tolerance is critical to maintaining stable performance under various environmental conditions. Particularly in industries with stringent reliability requirements like aerospace and medical devices, acetone testing ensures essential quality assurance by preventing issues such as surface marking loss or coating degradation.

Process of Acetone Testing

Preparation:

● Define testing objectives and requirements, select appropriate acetone solutions, and determine test parameters.

● Prepare test samples with clear identification for traceability and record-keeping purposes.

Solvent Exposure:

● Immerse or wipe components or circuit boards with specified acetone solutions under controlled exposure time and temperature.

● Record environmental parameters during exposure to ensure test repeatability and accuracy.

Performance Evaluation:

● Inspect the integrity of surface markings and the acetone resistance of coatings.

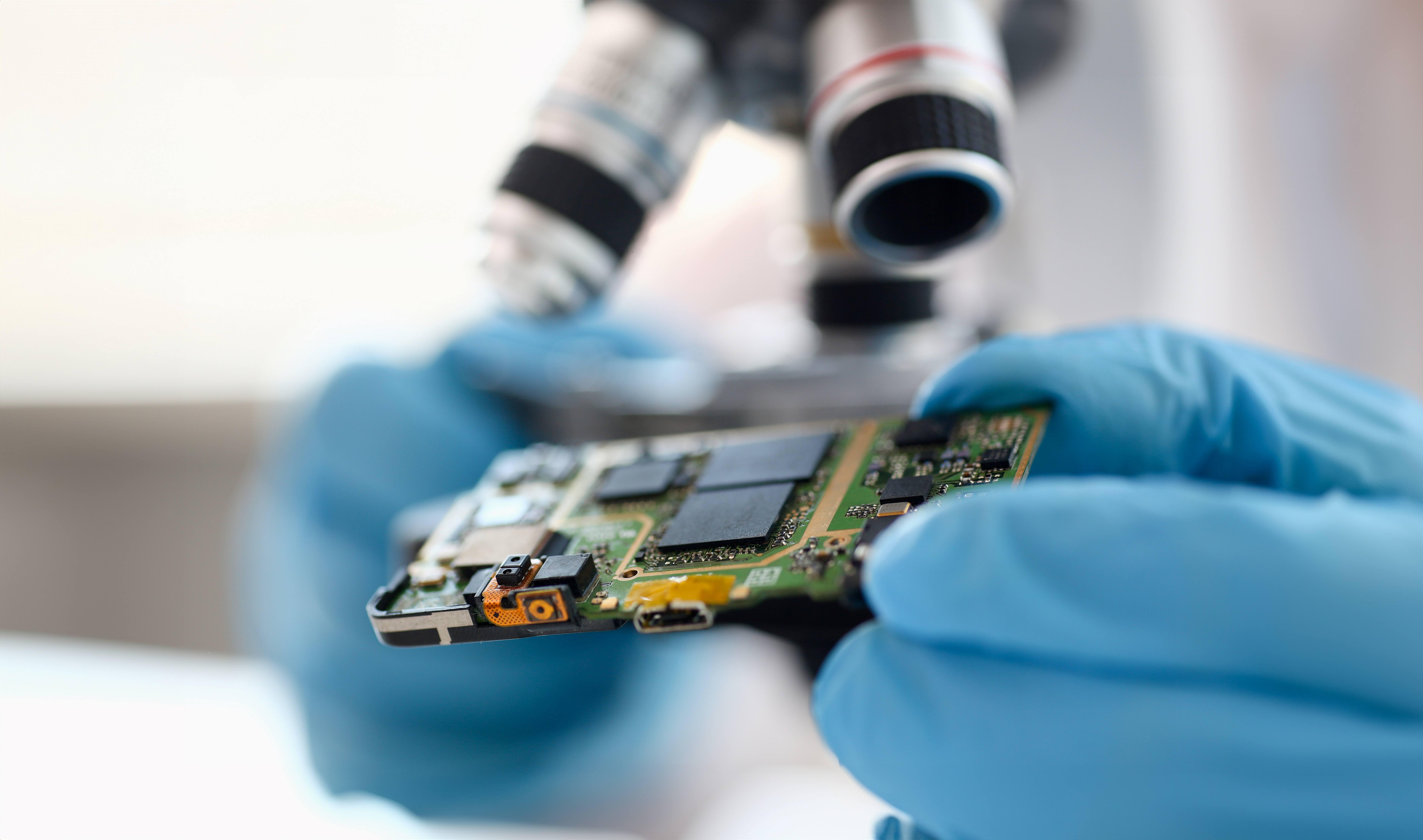

● Use microscopy or other analytical tools to evaluate printed circuit integrity and identify potential damage.

Reporting and Result Interpretation:

● Thoroughly document test results, noting any identified issues and potential quality risks.

● Compile detailed inspection reports for subsequent quality control and improvement references.

Acetone Testing Equipment

● Solvent testing chambers: Used to contain acetone solutions and test samples, ensuring uniform exposure.

● Microscopes and imaging equipment: Employed to detect and record changes in surface markings, coatings, and printed circuits. High-resolution microscopes reveal minor damages and defects.

In our laboratory, acetone testing is a critical means to ensure the quality and reliability of electronic components and printed circuit boards. Through advanced testing equipment and techniques, we provide precise and comprehensive analysis of acetone resistance, helping customers identify and avoid potentially defective components. This enhances overall product reliability and market competitiveness. Our testing services enable customers to confidently select and utilize the highest quality electronic components, thereby achieving superior product performance and safety.