Testing for Resurfacing

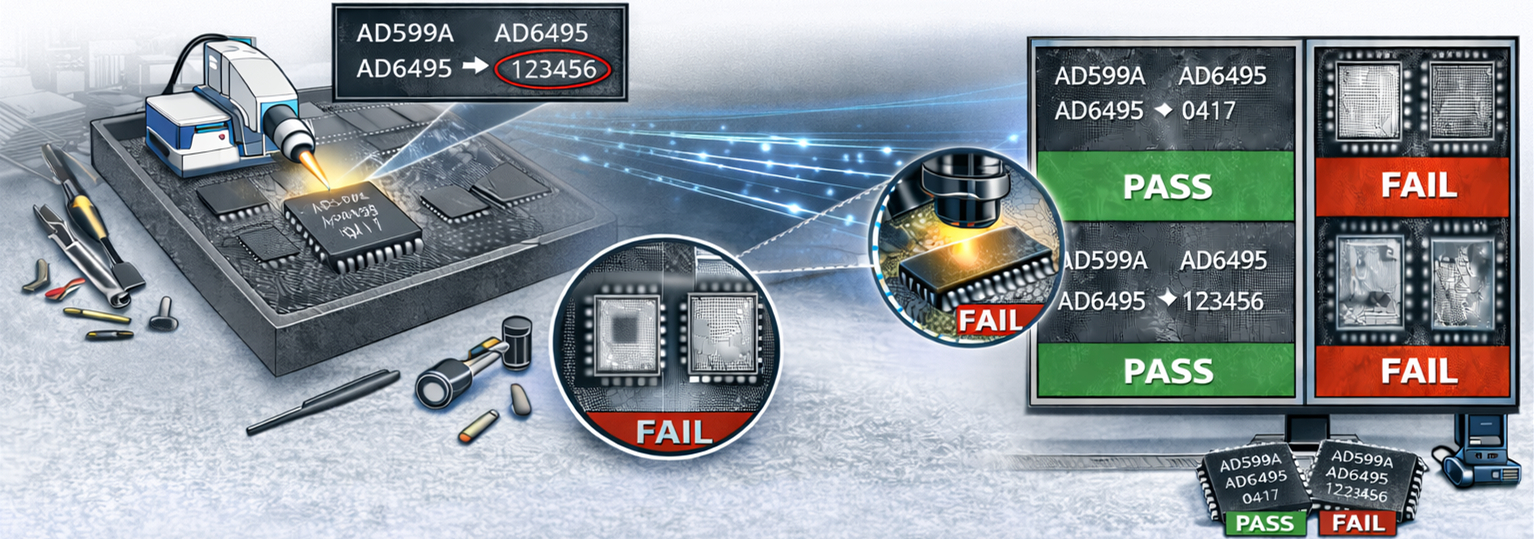

Testing for resurfacing is performed to determine whether an electronic component has undergone surface reprocessing or refinishing after original manufacture. Surface reprocessing may include coating, resurfacing, sanding, or other surface treatments intended to conceal original markings, surface damage, or prior modifications, and may be associated with subsequent remarking activities.

This testing is conducted by applying controlled solvent interaction to the component surface, followed by mechanical inspection where applicable, to evaluate surface and subsurface conditions. The test focuses on identifying physical indicators associated with surface reprocessing and does not involve electrical or functional testing.

Test Method

During testing, controlled solvent interaction is applied to designated areas of the component surface. Application methods and exposure conditions are controlled to ensure repeatability of the test process.

Following solvent interaction, the surface condition is examined. Where further confirmation is required, mechanical inspection techniques may be applied to evaluate the presence of surface coatings and the condition of underlying surface features.

No electrical measurements or functional verification are performed as part of this test.

Knife Scrape Testing

Knife scrape testing is performed as a controlled mechanical inspection method, typically following solvent interaction. A fine blade is carefully applied to selected surface areas to support evaluation of:

● The presence of surface coatings

● Coating adhesion characteristics and relative thickness

● Exposure of abnormal underlying surface features after coating disruption

Knife scrape testing is conducted in accordance with industry-recognized inspection practices and is used for supporting observation and evidence collection. It is not intended as a destructive test or as an acceptance criterion.

Evaluation Criteria

After completion of solvent interaction and knife scrape testing, microscopic examination is used to evaluate the component surface and underlying features. Evaluation focuses on identifying indicators associated with surface reprocessing, including but not limited to:

● Sanding, grinding, or polishing marks

● Residual or “ghost” markings from previous identification

● Abnormal surface texture, layering, or inconsistencies

● Irregular interface characteristics between coating layers and base material

Observed features may indicate that surface reprocessing has occurred.

Documentation and Records

All observations are documented and retained as inspection records. Documentation typically includes written descriptions and microscopic image records to support traceability and reporting.

Results from testing for resurfacing are used as supporting inspection information and are typically reviewed together with external visual inspection, testing for remarking, and other relevant inspection results. This testing does not provide a definitive determination of manufacturing history and is not used as a standalone acceptance criterion.