Testing for Remarking

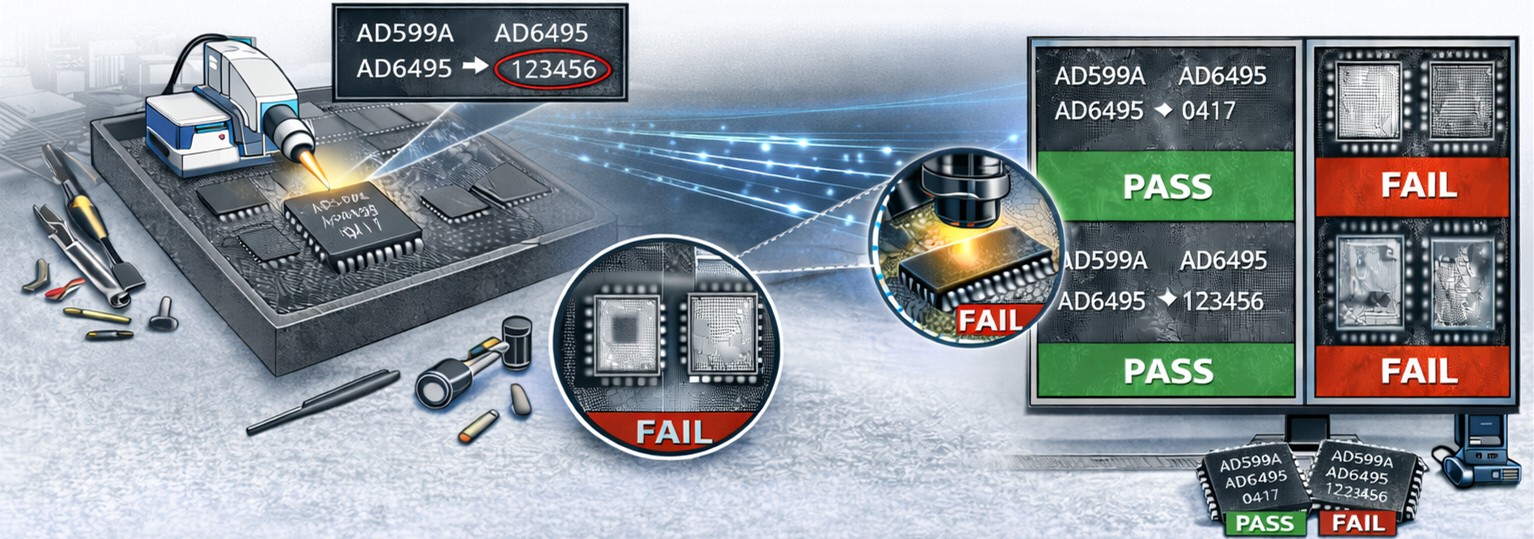

Testing for remarking is performed to determine whether an electronic component has been remarked. Remarking typically involves the removal, modification, or replacement of original markings and the application of new markings that may misrepresent part identity, date code, or classification.

This testing is conducted by applying selected solvents to the marking area under controlled conditions and evaluating the response of the markings. Evaluation of test results is performed using microscopic examination of the marking and adjacent surface features. The test focuses on the behavior and integrity of the marking material and does not involve electrical or functional testing.

Test Solvents

The following solvents are commonly used for testing for remarking:

● Mineral spirits

● Isopropyl alcohol (IPA)

The selected solvents are applied in a controlled manner to minimize unintended effects on areas outside the marking region.

Test Method

The test is performed by applying the solvent to the marking area using a suitable applicator. The application method and exposure time are controlled to ensure repeatability and consistency of the test.

After solvent interaction, the marking area is examined under optical magnification, typically using a microscope, to observe changes in the marking and surrounding surface. Examination under magnification allows identification of subtle features associated with marking stability and surface condition.

No electrical measurements or functional verification are performed as part of this test.

Evaluation Criteria

Evaluation focuses on identifying abnormal marking behavior or surface characteristics observed under microscopic examination, including but not limited to:

● Smearing, blurring, or partial removal of markings

● Dissolution or migration of marking material

● Irregular, poorly defined, or discontinuous marking edges

● Differences in marking thickness, texture, or durability when compared with similar parts

Observed behavior that deviates from expected marking characteristics may indicate potential remarking activity.

Documentation and Records

All observations are documented and retained as inspection records. Documentation typically includes written descriptions and microscopic image records of the marking condition before and after solvent application.

Results from testing for remarking are used as supporting inspection information and are reviewed together with external visual inspection and other relevant inspection results. This testing does not provide a definitive determination of authenticity and is not used as a standalone acceptance criterion.