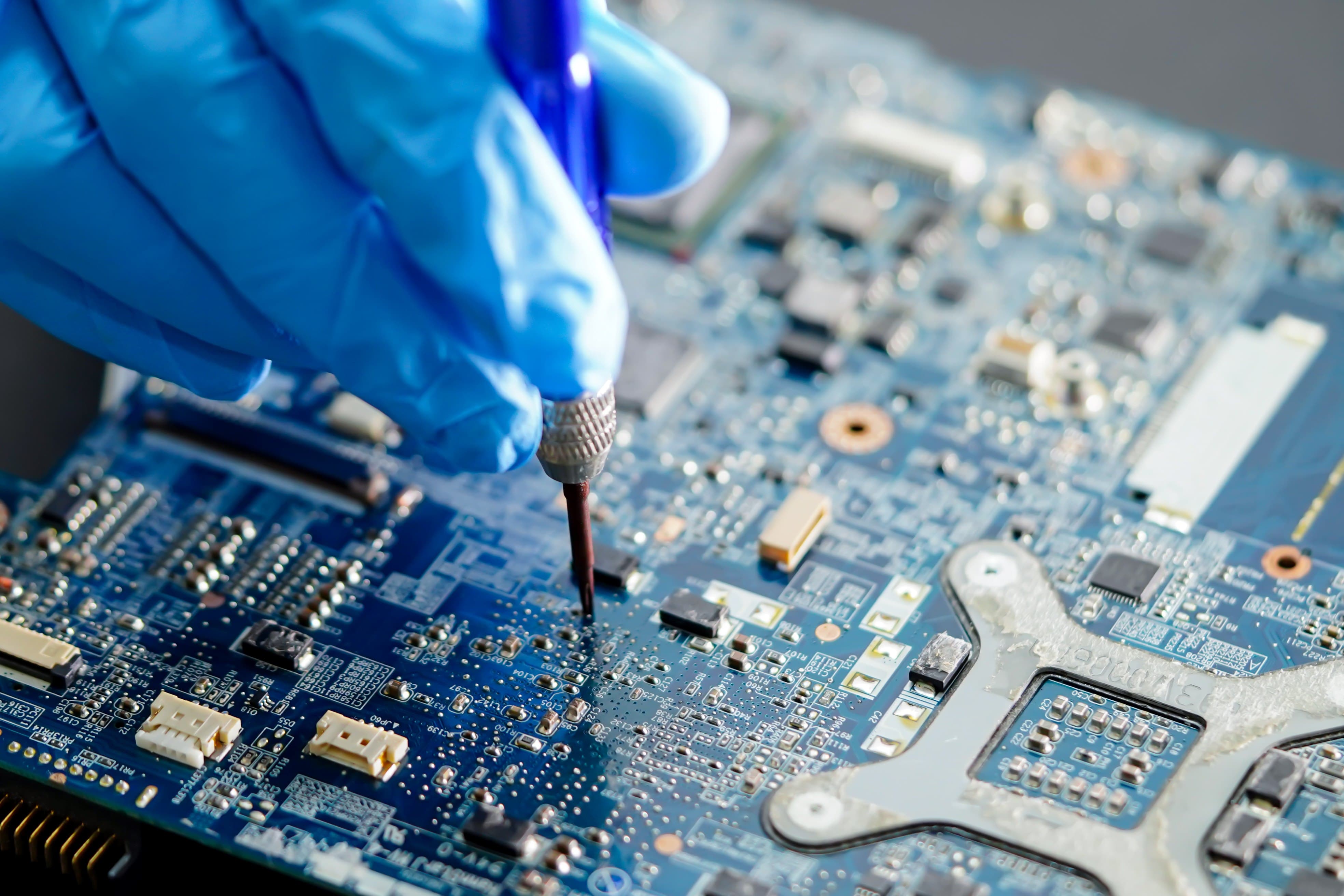

BGA Re-Flow Solderability Testing Service

BGA re-flow solderability testing is a critical quality control method used to assess the soldering performance of Ball Grid Array (BGA) packaged components during re-flow soldering processes. By simulating the actual re-flow soldering conditions of BGA components, this test measures soldering quality and joint reliability, providing essential process parameters and quality assurance to ensure the performance and reliability of electronic products. BGA re-flow solderability testing is widely applied in electronic manufacturing, semiconductor packaging, and high-reliability applications.

Basic Principles and Importance of BGA Re-Flow Solderability Testing

BGA re-flow solderability testing is based on the soldering behavior of samples under specific re-flow soldering temperature profiles. During re-flow soldering, the solder balls of BGA components melt at high temperatures, forming strong solder connections with the PCB pads. By measuring the morphology, strength, and electrical performance of solder joints, the quality and reliability of BGA components' soldering can be evaluated.

Good re-flow soldering performance is crucial for the quality of BGA components. It ensures mechanical strength of solder joints and reliability of electrical connections, preventing soldering defects such as cold joints, voids, and solder ball misalignment. In high-reliability applications such as aerospace, military, and medical devices, BGA re-flow solderability testing provides significant quality assurance, ensuring product stability and performance in demanding environments.

Process of BGA Re-Flow Solderability Testing

Test Preparation:

● Define testing objectives and requirements, select appropriate re-flow soldering temperature profiles and testing parameters.

● Prepare test samples, ensuring clean and oxide-free sample surfaces for optimal testing results.

Re-Flow Soldering:

● Secure BGA components on the test PCB, ensuring correct positioning and alignment of components.

● Set predefined temperature profiles in the re-flow soldering oven and perform re-flow soldering.

Cooling and Solidification of Solder Joints:

● After re-flow soldering completion, rapidly cool samples to solidify solder joints.

● Record temperature profiles and time parameters during re-flow soldering process.

Solder Joint Inspection and Analysis:

● Use microscopy and X-ray inspection equipment to examine the morphology of solder joints, shape, and position of solder balls.

● Evaluate mechanical strength and electrical connectivity performance of solder joints, identifying any potential soldering defects.

Report Preparation and Results Interpretation:

● Thoroughly document test results, including images of solder joint morphology, X-ray inspection results, and electrical performance data.

● Prepare detailed reports on BGA re-flow solderability testing for subsequent quality control and improvement references.

BGA Re-Flow Solderability Testing Equipment

● Re-Flow Soldering Oven: High-precision re-flow soldering equipment used to simulate actual production re-flow soldering conditions. Common equipment includes hot-air re-flow soldering ovens and infrared re-flow soldering ovens.

● Microscopy and X-Ray Inspection Equipment: Used to inspect and record the morphology of solder joints, shape, and position of solder balls. High-resolution microscopy and X-ray inspection equipment can reveal soldering defects and internal structures.

● Electrical Performance Testers: Used to measure the electrical connectivity performance of solder joints, ensuring conductivity and reliability of solder joints.

In our laboratory, BGA re-flow solderability testing is a crucial tool to ensure the soldering quality of electronic components and PCBs. By employing advanced testing equipment and technology, we provide precise and comprehensive soldering performance analysis for our clients. This not only helps identify and avoid potentially defective materials but also enhances overall product reliability and market competitiveness. Our BGA re-flow solderability testing services enable clients to confidently select and use the highest quality soldering materials and processes, thereby achieving superior product performance and safety.