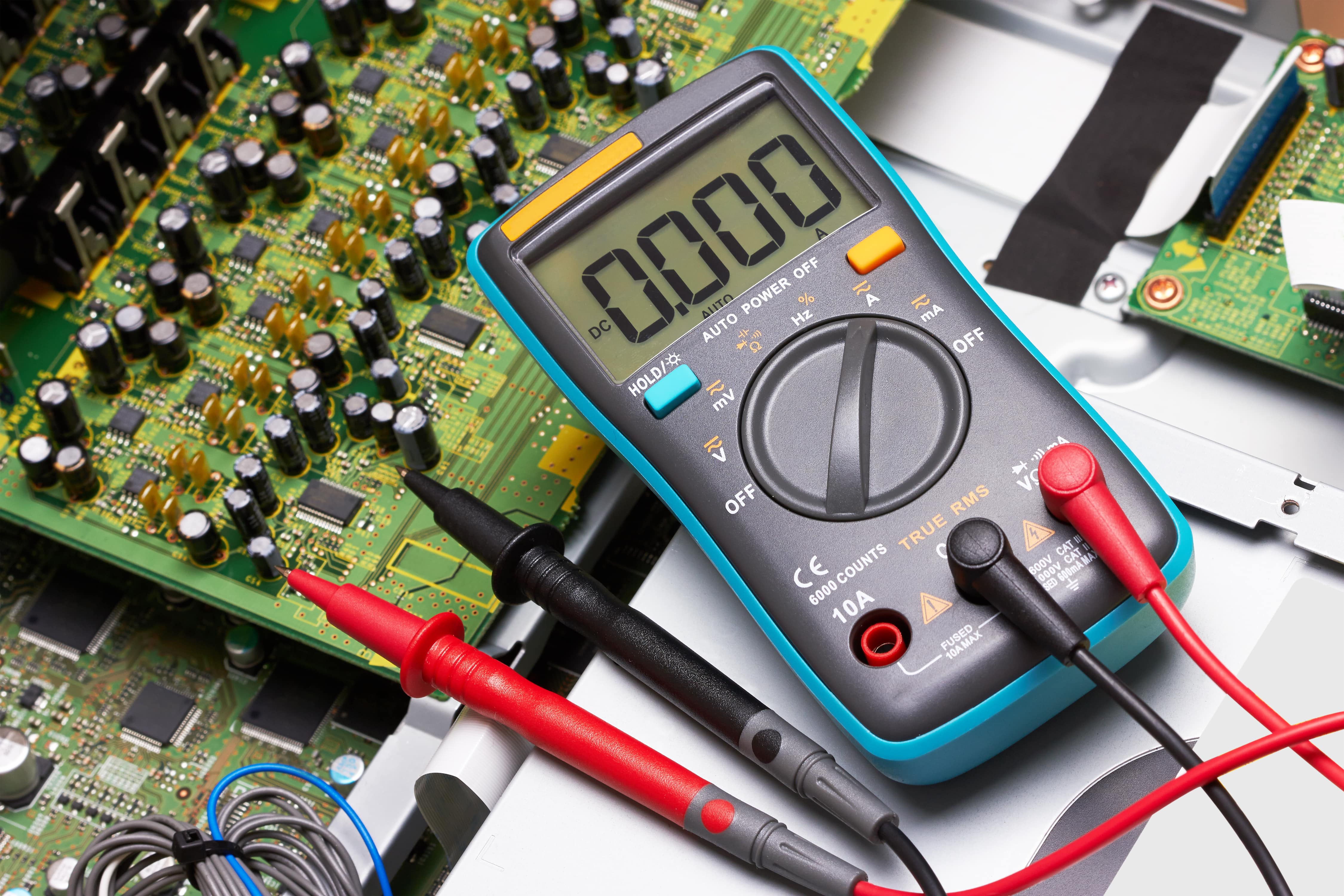

Functional Testing Services

Functional testing is a critical quality control and verification method used to assess the functionality and performance of electronic components and systems. This testing thoroughly examines the functions, performance, and reliability of products by simulating actual working conditions, ensuring their stability and efficiency in various applications. Functional testing is widely applied in electronic manufacturing, semiconductor design, communication equipment, automotive electronics, and high-reliability application areas.

Basic Principles and Importance of Functional Testing

Functional testing evaluates the functionality and performance of electronic components and systems through a series of rigorous testing processes. Test content typically includes input-output testing, signal integrity testing, response time testing, power consumption testing, and environmental tolerance testing. These tests identify defects and potential issues in products, ensuring their stability and efficiency under various working conditions.

The functionality and performance of electronic components and systems are crucial to the overall product quality. Through functional testing, products are ensured to meet design specifications and application requirements, preventing system failures and performance degradation due to functional failures or poor performance. In high-reliability applications such as aerospace, military, and medical equipment, functional testing provides significant quality assurance, ensuring product stability and performance in harsh environments.

Functional Testing Process

Test Preparation:

● Define testing objectives and requirements, select appropriate testing equipment and parameters.

● Prepare test samples, ensuring they are undamaged and clearly labeled for optimal test results.

Input-Output Testing:

● Check the basic functions of the product, including the correctness and consistency of all inputs and outputs.

● Ensure the product produces the expected output under all input conditions without errors or failures.

Signal Integrity Testing:

● Measure the signal transmission characteristics of the product to ensure no distortion or interference.

● Use high-frequency signal generators and oscilloscopes to measure signal amplitude, phase, and spectral characteristics.

Response Time Testing:

● Measure the response time of the product under various input conditions to ensure it meets performance requirements.

● Use specialized testing equipment to evaluate the product's delay and processing speed.

Power Consumption Testing:

● Measure the power consumption of the product under different operating conditions to assess its energy efficiency and heat dissipation performance.

● Use power meters and thermal imaging cameras to record power consumption data and temperature distribution.

Environmental Tolerance Testing:

● Test the product under high temperature, high humidity, and other extreme environmental conditions to assess its reliability and durability.

● Use thermal testing equipment and environmental simulators to mimic the harsh environments the product will experience in actual use.

Data Collection and Analysis:

● Use testing instruments to collect performance data of the product under different conditions.

● Use professional software to process and analyze the test data, generating detailed performance charts and reports.

Report Compilation and Result Interpretation:

● Document the test results in detail, including functional testing results, performance data, and environmental tolerance testing results.

● Prepare comprehensive functional testing reports for subsequent design validation and quality control reference.

Functional Testing Equipment

● High Precision Function Testers: Used to detect the basic functions and performance of products, ensuring they are within specification ranges.

● Signal Generators and Oscilloscopes: Used to measure the signal transmission characteristics of products, ensuring no distortion or interference.

● Specialized Testing Equipment: Used to measure the response time and processing speed of products.

● Professional Analysis Software: Used to process and analyze testing data, generating performance charts and test reports.

In our laboratory, functional testing is an essential tool to ensure the performance and reliability of electronic components and systems. By utilizing advanced testing equipment and techniques, we provide our clients with precise, detailed product performance analysis. This not only helps clients identify and avoid potentially defective products but also enhances the overall reliability and market competitiveness of their products. Our functional testing services ensure that clients can confidently select and use the highest quality electronic components and systems, thereby achieving superior product performance and safety.