External Visual Inspection

As an electronic component laboratory, we play an important role in supporting customers as they evaluate the reliability, authenticity, and overall quality of electronic components used across a wide range of industries, including industrial electronics, automotive systems, medical devices, and consumer products. External Visual Inspection (EVI) is one of our core inspection services and represents a critical first step in the overall quality evaluation process.

EVI focuses on the systematic examination of component surfaces, markings, packaging, and external physical features. By identifying visible anomalies at an early stage, external visual inspection helps reveal potential quality concerns, counterfeit risks, and deviations from industry expectations before components are introduced into production lines or end-use applications. This early screening supports informed decision-making and effective risk control throughout the supply chain.

The Importance of External Visual Inspection

● Counterfeit Risk Screening

Counterfeit electronic components continue to present significant challenges in the global electronics market. These components may appear acceptable at first glance but often fail to meet original manufacturer specifications, performance expectations, or long-term reliability requirements, potentially leading to system malfunction or safety risks in critical applications.

Through external visual inspection, our laboratory carefully examines component markings, labels, packaging conditions, surface finishes, and physical characteristics to identify potential indicators of counterfeit risk. Typical warning signs include inconsistent or incorrect markings, abnormal fonts or logos, evidence of surface rework, unusual material appearance, or packaging that does not align with known manufacturer practices. While EVI alone does not constitute definitive counterfeit confirmation, it serves as an effective preliminary screening tool that helps customers reduce exposure to high-risk components.

● Quality Assessment

External visual inspection also plays a key role in quality assessment. Visible defects such as scratches, cracks, incorrect markings, lead deformation, corrosion, contamination, or structural abnormalities may indicate improper handling, manufacturing defects, or aging-related degradation. Although these issues are external in nature, they often reflect underlying conditions that can negatively affect component functionality, assembly yield, or long-term reliability.

By identifying such defects prior to assembly or use, customers are able to take appropriate actions, reduce rework costs, minimize failure risk, and improve overall product quality.

● Compliance Support

External visual inspection serves as a supportive element in compliance evaluation. By identifying abnormal markings, packaging inconsistencies, or suspicious external features, EVI can help highlight potential non-conformance with regulatory or customer requirements. When appropriate, external visual inspection results may be combined with documentation review or additional testing methods to support assessments related to RoHS, REACH, or other regulatory considerations.

External Visual Inspection Process

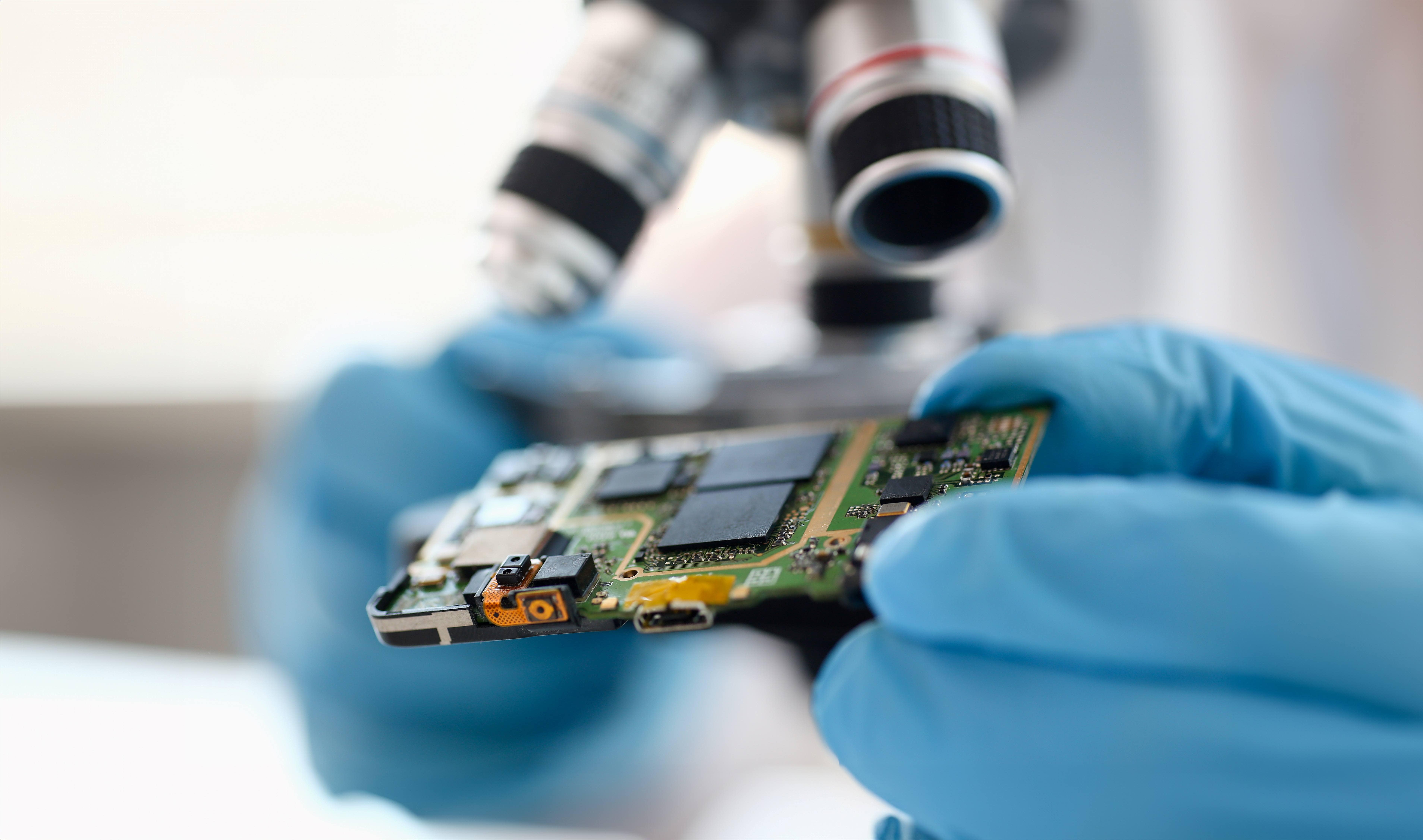

● Detailed Visual Examination

External visual inspections are performed by trained inspection personnel under controlled lighting conditions using stereo microscopes. Components are systematically examined to identify deviations from standard appearance, workmanship quality, and known product characteristics, with particular attention given to markings, lead condition, package integrity, surface consistency, and signs of rework or damage.

All external visual inspection activities are conducted in accordance with industry-recognized visual inspection practices, customer-specific requirements, and internal laboratory procedures. This structured approach helps ensure consistency, repeatability, and traceability of inspection results.

● Documentation and Reporting

During inspection, stereo microscopes are used to observe key external features and abnormal conditions, and relevant images are recorded to support report preparation and result traceability. Inspection findings are documented in a standardized inspection report that provides customers with clear, objective, and verifiable evaluation results to support technical review and quality decisions.

● Evaluation and Recommendations

Based on inspection findings, the laboratory provides professional evaluation results and recommendations, such as acceptance, segregation, or further testing, in accordance with customer requirements and the nature of the observed conditions.

Primary Inspection Equipment

●Stereo Microscopes

Used for external inspection of electronic components, suitable for observing lead condition, surface damage, package integrity, marking clarity, and overall appearance consistency.

●X-ray Inspection Equipment

Applied as a complementary method when external inspection results indicate potential internal structural risks, such as voids, cracks, or solder-related abnormalities that cannot be confirmed through visual inspection alone.

External visual inspection is an important element of quality evaluation and is most effective when combined with electrical testing, X-ray analysis, and other supplementary inspection methods to form a comprehensive quality control approach.

In our laboratory, external visual inspection serves as the first line of quality risk screening, helping customers reduce risk, improve transparency, and build confidence in the electronic components they use. Through disciplined inspection processes, structured reporting, and continuous personnel training, we remain committed to supporting high-quality and reliable electronic products in the global market.